For this reason, the Bioenergy 2020+ competence centre established a working group focusing on automation and control in close cooperation with the Institute of Automation and Control at TU Graz.

Model-based control strategies for different renewable energy technologies, such as biomass combustion and solar thermal systems, as well as strategies for their optimal interaction will be developed in the course of the cooperation. A key part of the research focuses on developing control-oriented mathematical models for the respective processes. This means that the models reproduce the main dynamic characteristics of the processes sufficiently well but still serve as a suitable basis for controller design.

Joint research projects

In recent years a number of joint research projects have been carried out. Numerous master’s and doctoral theses have been written in the course of the research projects, leading to a number of scientific publications in renowned journals and presentations at high-profile conferences.

A good example of the collaborative research performed in recent years focused on the model-based control of a biomass gasification combined heat and power (CHP) plant that uses dual fluidised bed biomass steam gasification. The research project is outlined below.

The possibility of simultaneously producing sustainable heat and power means this technology is essential for implementing sustainable energy systems. However, it is currently facing financial challenges due to the high price of raw materials (such as wood chips) and low prices for products (like electricity and heat). In order to maintain, carry out research on and enhance this key technology on an industrial scale, its economic efficiency needs to be increased. So the project investigated various options for improving interaction between the different processes by means of advanced control.

The project was completed in summer 2018 with the successful evaluation of the developed control strategies at an industrial-scale biomass gasification CHP plant in Senden, Germany, owned by the company Blue Energy Syngas (see Figure 1). The main result is an innovative control strategy based on the joint control of an essential process variable, the pressure at the inlet of the gas engines producing the electricity, with two actuators each operating in different frequency ranges.

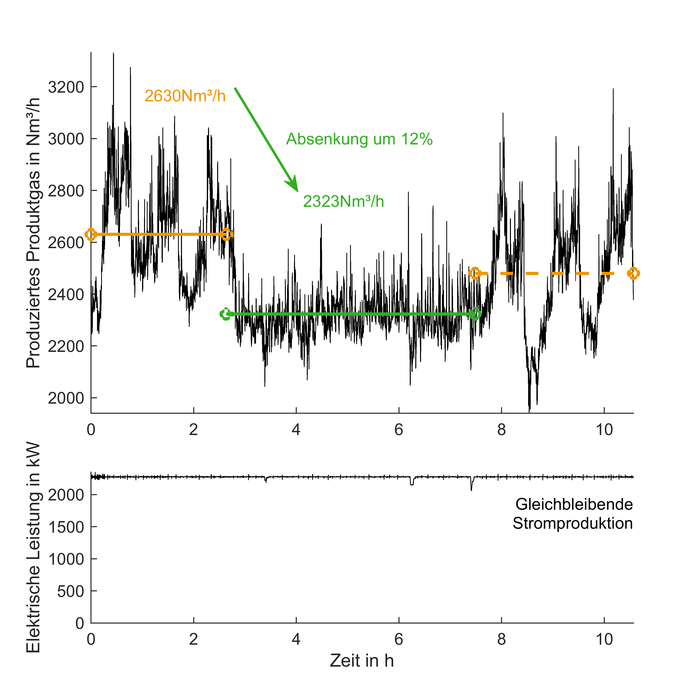

The evaluation of the innovative control concept revealed that the amount of product gas required, and thus the requisite amount of fuel, could be reduced by 12% in partial load operation while maintaining the same level of electricity production (see Figure 2). At full load, the reduction was estimated at around 7%. Since fuel accounts for a large proportion of the plant’s operating costs, these costs could be significantly reduced by means of this particular control engineering measure. The project was funded by the Austrian Research Promotion Agency (FFG) as part of the NATS BRIDGE Early Stage programme. Other project partners included the Institute of Chemical, Environmental and Bioscience Engineering at TU Wien and the company Repotec.

Figure 2: Significant reduction in the amount of fuel required for the same level of electricity production.

Apart from the work on the control of different renewable energy technologies, there is a strong focus on the interaction of these technologies at the systemic level, since the shift towards a renewable energy and resource system can only be achieved by means of an appropriate combination of different technologies. This is mainly because of the volatility of many renewable energy technologies: their output is nor controllable, or only partly controllable, and mainly depends on environmental conditions (e.g. wind or sunlight). For this reason, different technologies have to be combined in an appropriate, typically more decentralized way to fulfil all the needs of final consumers. However, the resulting cross-sectoral energy systems, often referred to as microgrids, are becoming more complex and currently control methods are not yet capable of operating such complex systems reliably and efficiently.

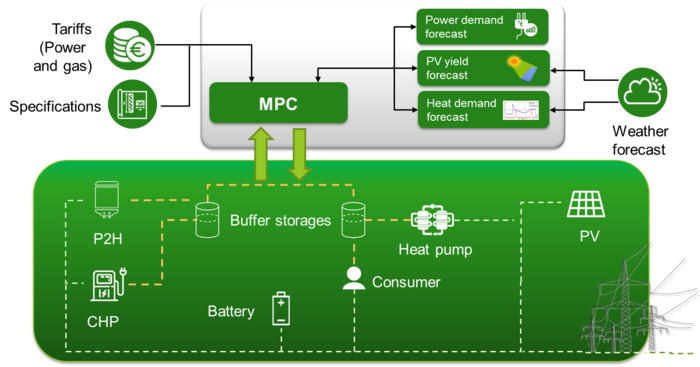

In recent years, several joint research projects on the optimal control of microgrids have been carried out. Essentially, the approaches pursued are based on the concept of model predictive control (MPC). This approach uses simple mathematical models describing the behavior of different energy technologies and weather forecast data, as well as the tariffs for different consumables (e.g. natural gas, biomass, etc.) to predict the optimal future operating strategy for the different technologies and forms of energy storage. MPC continuously calculates (e.g. every 15 minutes) the optimal actuating signals for a forecast horizon (e.g. 48 hours) with the aim of minimising a defined cost function (e.g. primary energy use). The first interval of the calculated manipulated variables is then applied to the system and the MPC calculation starts anew, with updates to both the initial state and the different forecasts used. In this context, the development of suitable methods for forecasting the yield of the prevalent volatile energy sources (e.g. photovoltaic systems) and consumers’ future demand for electricity and heat is particularly important. On the one hand these methods should be general and adaptive and on the other they should be as simple as possible so that they can be implemented without excessive effort.

Since the optimal interaction of different renewable energy systems is one of the major challenges of the move towards a renewable energy and resource system, the two partners are also trying to combine their specific research results to create a more general and modular framework for the optimal, predictive control of microgrids. This will take the form of modular energy management system for cross-sectoral energy systems which is designed to support the practical application of research findings (see Figure 3).

Figure 3: Energy management system for cross-sectoral energy systems (microgrids).