Aeroacoustics of confined flows in electric vehicles

This project is in cooperation with AVL List GmbH and the Institute of Fluid Mechanics and Heat Transfer at TU Graz (http://www.isw.tugraz.at) and is funded by the Austrian Research Promotion Agency (FFG, Nr. 874874).

The importance of acoustic comfort in electric vehicles is strongly increasing. Due to the fact that main noise sources such as the combustion engine is no longer present, the focus for the acoustic comfort concentrates on acoustic sources, which have been masked by the combustion engine, as well as new acoustic sources arising due to high integration of necessary components. Typical examples are electric vehicles powered by fuel cells. The high integration of all components leads to flow guiding pipes, which are sub-optimal and may result in strong flow induced sound sources. Therefore, a numerical simulation environment capable to predict the flow and acoustic behaviour is of outermost importance. Thereby, possible problems can be detected and the different configurations can be virtually optimized before a first prototype is built.

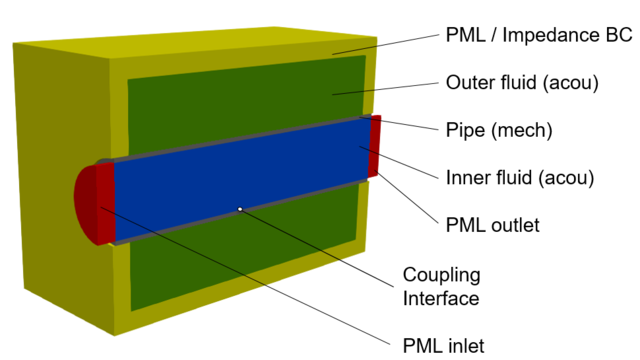

The goal of this research project is the development of a simulation environment, which can precisely compute the sound mechanism in flow guided pipes and its radiation. Thereby, we aim to physically understand the aeroacoustic mechanism, which will allow us to strongly reduce the sources due to geometry changes and material properties. In addition, such a simulation environment will allow us to understand the transfer of the sound through the structures and its radiation, and will allow to predict optimal placement of sound absorbing materials. Thereby, the open source multi-physics finite element solver openCFS (https://opencfs.org) is used for the simulation of the acoustic wave propagation, transmission and vibro-acoustic radiation. Several acoustic analogies, namely the Lighthill analogy, vortex sound, and the perturbed convective wave equation, as well as stochastic sound computation methodologies, are deployed. The computational schemes are applied to a straight pipe, a pipe with half-moon shaped aperture, a 90° bend and Y-junction, which are typically found in applications of automotive engineering.

Computational aeroacoustic (CAA) simulation setup for the straight pipe

In order to validate the numerical simulations, measurements are performed on a setup that represents the simulation model. Thereby, state of the art measurement equipment is utilized. High performance pressure transducers (Kulite), differential pressure sensors, acceleration sensors, microphones, and a flow meter provide the necessary validation data. A modular arrangement allows a simple adaption of the measurement object (flow guiding structure) and modification of sensor positions. Flow velocities of 40 m/s (pipe inner diameter 50 mm) can be achieved due to a high pressure radial fan.

Measurement setup

With the combination of the numerical model and the modular measurement setup a deep insight into the mechanisms of sound generation of confined flows is possible.

Publications:

- S. Schoder and M. Kaltenbacher. “Hybrid aeroacoustic computations: State of art and new achievements”. In: Journal of Theoretical and Computational Acoustics 27(4), 2019. https://doi.org/10.1142/S2591728519500208

Period

- 2019 - 2022

Funding

- FFG

Members

Manfred Kaltenbacher

Tel.: +43 (0) 316 / 873 – 7250

Email