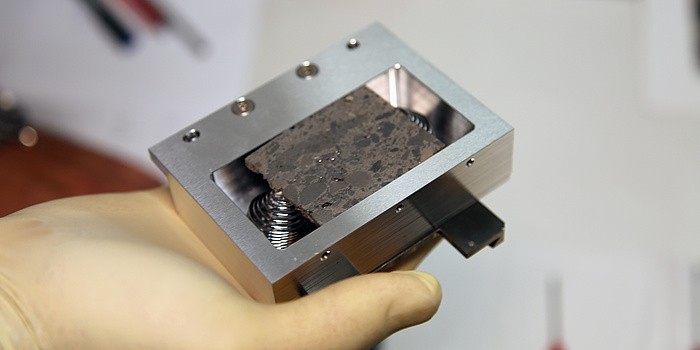

The wafer-thin black flake shines like a flattened precious stone. The flake is locked in a silver sample container sitting on a clean tray waiting to be pushed into a large machine on the opposite side of the lab. The machine is a field emission microprobe and the sample is a piece of concrete. After being ground with diamond powder and coated with carbon, even something as hum-drum as this takes on a beautiful appearance.

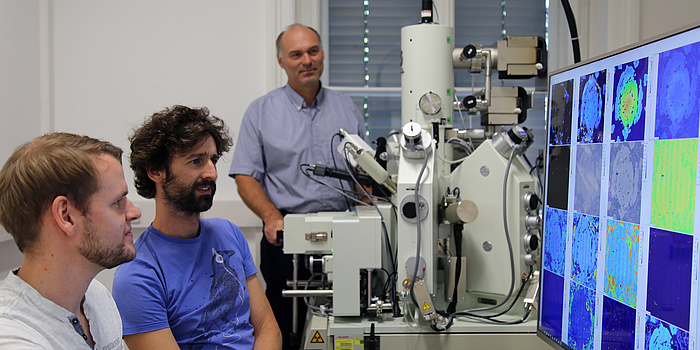

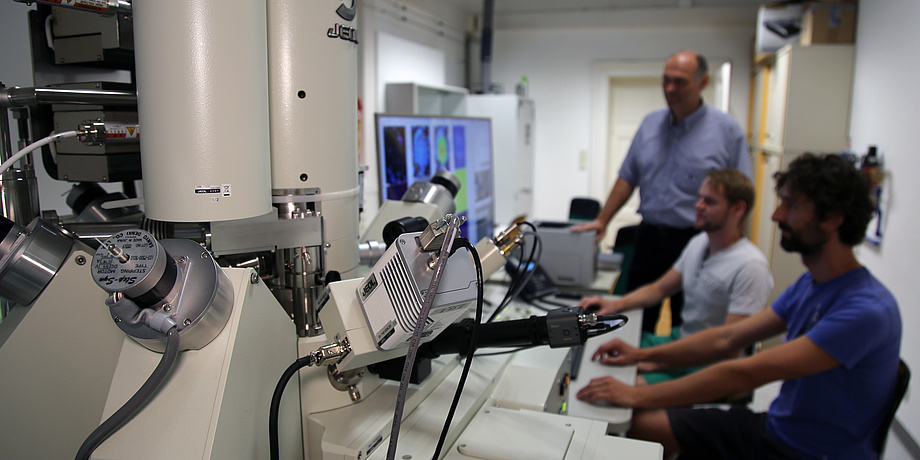

Of course, this process is about more than just aesthetic appeal, as Florian Mittermayr of the Institute of Technology and Testing of Construction Materials at TU Graz explains: “We need to prepare our samples meticulously so that they can be accurately analysed.” The samples are precisely ground so that their surfaces can be correctly measured. The carbon coating makes the sample’s surface conductive, and it can then be examined using an electron microscope. But a field emission microprobe is capable of much more than a conventional electron microprobe. “This allows us to zero in by additional orders of magnitude,” smiles Christoph Hauzenberger of the Institute for Earth Sciences, who heads the lab on behalf of the University of Graz.

Concrete can be so beautiful - when it has been prepared for examination in the field emission microprobe.

The smaller the better

When standard microprobes and scanning electron microscope are stretched to their limits, the field emission microprobe comes into its own. “With our device we can offer higher resolutions, which allows for full-quantitative chemical analysis,” Hauzenberger points out. This means that a variety of elements present in the sample can be pinpointed. In addition, the entire sample can be measured, producing a “map” of the different elements that shows the levels in which they occur. “It’s quite simple: the lighter it shows up, the more of it there is,” Mittermayr explains.

The TU Graz researcher shows how the device operates. First, he prepares the concrete sample and slides it into the machine’s high-vacuum environment. A high vacuum differs from a normal vacuum in that the pressure is two orders of magnitude lower: 10-8 bar as opposed to 10-4. An emitter gives off electrons which are focused onto the sample by an electromagnetic lens. Conclusions on the composition of the material can be drawn on the basis of how the electrons interact with the sample – whether they are scattered or reflected by it. “Our device has five wavelength-dispersive spectrometers which we can use to measure a wide range of elements at the same time,” says Mittermayr. He uses the field emission microprobe primarily for research into building materials developed by the institute for specific purposes such as tunnel construction and wastewater systems.

New research questions welcome

At present, the field emission microprobe is mainly used by the NAWI Graz partner institutes at TU Graz and the University of Graz. However, the laboratory is also open to external researchers and available for various collaborative projects and contract measurement services.