Thanks to Gerhard Holzapfel, Justyna Niestrawska moved to TU Graz to take up her place in his working group. He is head of the Institute of Biomechanics, has written several standard works on the topic of continuum mechanics, developed well-known material models, and has headed the TU Graz lead project Mechanics, Modeling and Simulation of Aortic Dissection since the beginning of 2018.

Since 2014 she has been conducting research at TU Graz on the stress limits of the aorta abdominalis – the main artery supplying the organs in the abdominal area. A very serious disease of the aorta is aortic aneurysm, which occurs predominantly in persons aged 65 or older, and in the worst cases ends in an aortic rupture. Operations are high risk and a decision to operate must be taken on the basis of as much information as possible. ‘Currently operations are carried out with an aneurysm size of five centimetres in women and five and a half centimetres in men. But the size of an aneurysm is not the only factor which defines the risk of rupture,’ explains Niestrawska. In her doctoral thesis she has worked on being able to predict the course of the disease, which can be represented and observed using high-definition imaging techniques. ‘Some aneurysms under five centimetres have torn, and some have grown to ten centimetres without rupturing.’ Together with a team of researchers from TU Graz and the Medical University of Graz the young researcher wants to demonstrate the stress limits of the aorta walls using mechanical stress tests.The ‘garden hose’ inside our body

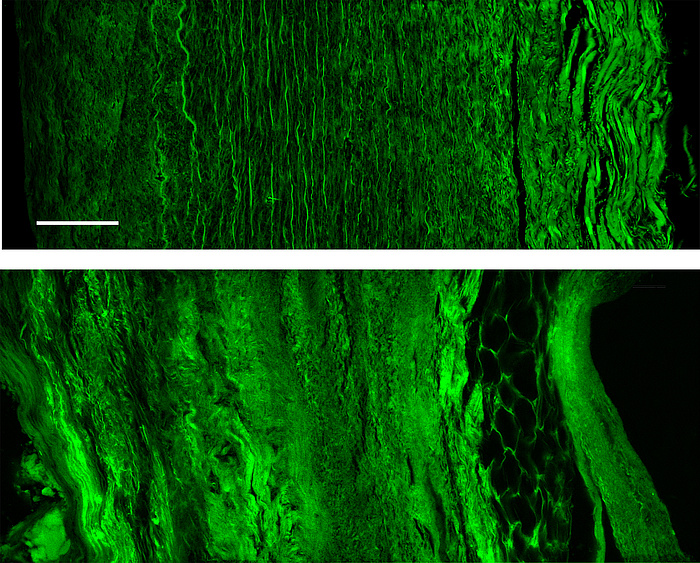

In its healthy state, the aorta consists of three easily distinguishable layers which, together with their different structures, ensure that the aorta is flexible and stable and that it can withstand the pressure of pulsating blood without being damaged. The innermost layer is called the tunica intima, consists of endothelial cells and is mechanically negligibly thin in a young person. The tunica media – the middle layer – gives stability to the vessel wall with its straight fibres. ‘You can basically compare the structure of the aorta with a garden hose. As in a garden hose small fibres form a tissue which keeps it flexible and stable at the same time,’ explains Niestrawska. The outermost layer – the tunica adventitia – forms a kind of protection against excess pressure and its corrugated fibrous structure allows the artery wall to expand without damage in the case of a sudden severe stress.Mechanical tests show the stress-bearing capacity of the artery wall

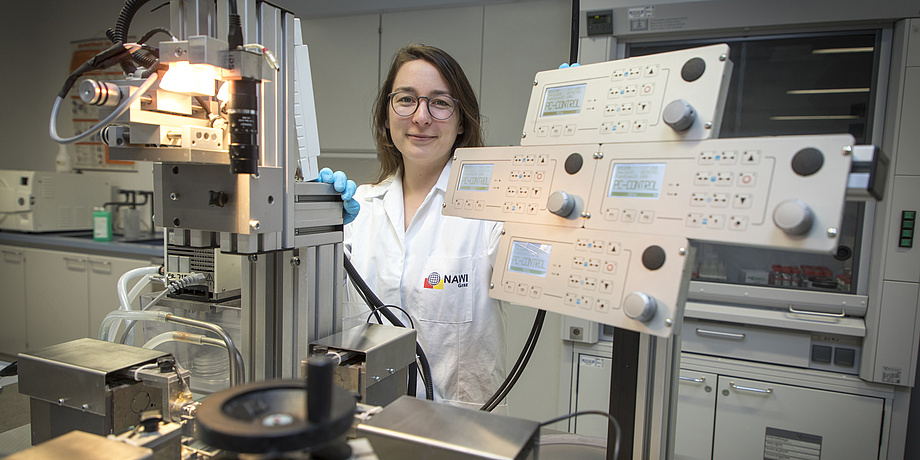

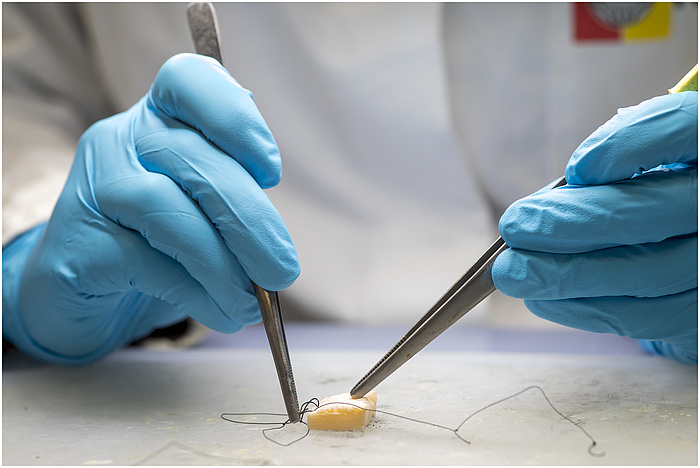

To obtain reference data, the team initially studied healthy blood vessels. Using a biaxial stretching device developed at the Institute, small pieces of tissue are subject to stress in two directions at different forces. ‘First of all we tested the complete wall, and then we separated the individual layers from each other and clamped them in the tension device,’ explains Niestrawska.

For their research results on the aorta abdominalis, which is explained in the paper ‘Microstructure and mechanics of healthy aneurysmatic abdominal aortas: experimental analysis and modelling’ and published in the Journal of the Royal Society Interface, Justyna Niestrawska and the research team of TU Graz and Klinische Abteilung für Gefäßchirurgie, Universitätsklinik für Chirurgie and Diagnostik und Forschungsinstitut für Pathologie of the Medical University of Graz were awarded the Aorta Prize of the German Society of Vascular Surgery and Vascular Medicine.

The next significant differences became apparent under stress in the stretching device. ‘In the healthy media, the structuring collagen fibres are embedded in an elastic layer so that the aorta can expand without any problems. But in the course of disease, this layer is the first to be degraded, and the fibres lose their orientation. We saw more behaviours in the mechanical tests. With some samples, there was no resistance at the beginning but after some time the fibres very suddenly became completely stiff. In the case of other samples, the fibres were completely stiff right at the beginning. Under these conditions, of course, the risk of rupture to the artery wall strongly increases because the material cannot expand any more under increased pressure,’ explains Niestrawska.

Imaging techniques could show the course of the disease

Building on her basic research, Niestrawska would like to check her hypotheses in tests on living organisms in a next step. She has also got some ideas for a real application: ‘In our work we could find indications for a course of disease which could be recognised and observed by certain high-resolution imaging techniques.’ In any case she would like to continue research in her field and is already planning to submit a new project application after her doctoral thesis.This project is anchored in the FoE ‘Human & Biotechnology’, one of five research foci of Graz University of Technology.

You can find more research news from this field in Planet research.