A large, high room with huge screens, where dozens of people sit in front of their computers and keep an eye on the data relevant to them – this is more or less how we know an ESA or NASA ground control from television broadcasts of large rocket launches. The ground control of the Institute for Communication Networks and Satellite Communication at TU Graz shows that operating successful satellite missions does not have to be quite so pompous. Admittedly, no rockets take off from here, but for the history of Austria as a space nation it is a very significant place. After all, the first Austrian satellite was built in the same building and its first signals from Earth orbit were also received here.

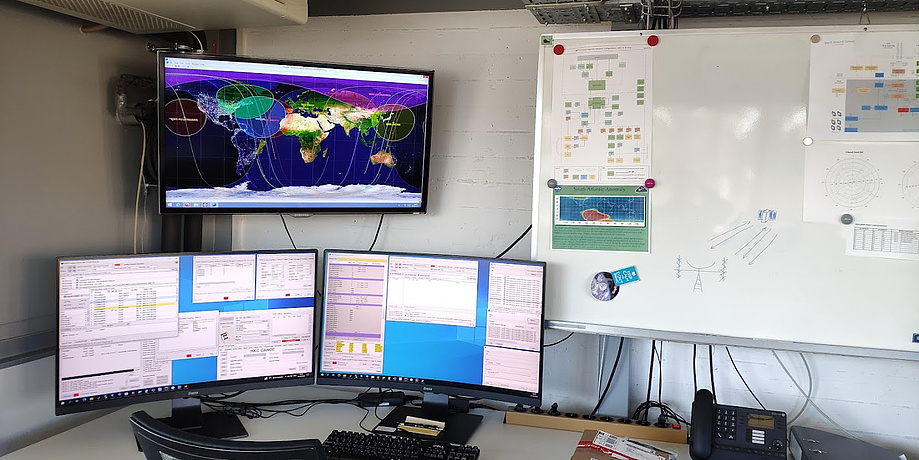

However, anyone entering the small room under the roof of the building at Inffeldgasse 12 would not immediately suspect this. A few screens showing the orbits of various satellites and important measurement data, a rack of computer hardware and functional furniture make it appear rather sparsely furnished. But the visuals play a very subordinate role here; the data that reaches the screens and subsequently the researchers from the antennas on the roof or the surrounding buildings via the hardware is what really counts.

Looking into space since 2013

The main focus of sky observation is the TUGSAT-1 satellite, which has been in space since 2013, and then also the nanosatellite PRETTY after its launch in 2023. The ground control serves additionally as a backup station for OPS-SAT, which was also built at TU Graz and launched into space in 2019. The example of TUGSAT-1 shows that technology and precise preparation are crucial to getting what you want out of a satellite. This is because sending and receiving data can only be done during a fly-by (better known in specialist circles as a pass), which takes between eight and 15 minutes, depending on how far above the horizon the satellite is and thus within range.

Testing is actually the most critical part of space missions

To ensure that everything runs smoothly here, the receiving antenna was not long ago fitted with better rotors so that it can rotate quickly enough when the satellite flies directly over the station. Because the more precisely the antenna can be aligned, the higher the possible transmission rates to and from the satellite.

The role of the mission control centre

The orientation of the satellite itself also plays an important role in data transmission. To ensure that this is correct, as soon as the satellite appears above the horizon, command lists for upcoming fly-bys are sent in advance. As a result, it starts aligning itself a few minutes before its pass and is thus ready to transmit and receive when it comes into range.

Once everything is aligned and the data arrives, it is the turn of the hardware and software of the ground control. This combination is called the mission control centre and is used on the one hand to modulate the data stream so that the satellite and ground control also understand it, and on the other hand to evaluate and prepare the data and to plan and analyse scripts. So that not everyone can interfere with the communication between ground and space, both sides have their own address through which they can reach each other. And in addition to the exact alignment, amplifiers are interposed to make the signal strong enough.

Simply switching off and on again

For Manuela Wenger, the most important thing from this data stream is the satellite’s health data and her commands for the satellite, while the scientific data goes to the relevant research groups. “First of all, we have to check whether the satellite is currently working OK or not – afterwards I can download all the data. Because I need to know not only whether it is currently working alright, but whether it was working alright for the entire 90 minutes of its last orbit around the Earth,” says Manuela Wenger. If something was wrong, she receives an alert and can intervene manually on the next pass to fix it. They also like to resort to a tactic known on Earth as an IT remedy: switching something off and on again. “For example, if I get an alert that the satellite has lost its position, then I reset the computer, reboot it and reload everything.”

Find more information and stories on the activities of TU Graz in outer space in our dossier “TU Graz in Space”

In between, there are also controlled restarts, as the higher radiation in orbit causes charges that can lead to short circuits. These can be avoided by a controlled switching off and on again. This has proven successful for TUGSAT-1. “So far, it has worked like this for ten years,” says Manuela Wenger. In order for them to function for even one minute in space, satellites such as TUGSAT-1, OPS-SAT and PRETTY have already travelled a long way before their launch. To be able to do this, quite a lot of infrastructure is necessary at TU Graz.

How do I make a satellite ready for flight?

After all, Graz University of Technology (TU Graz) built these three satellites itself and so had to ensure that they would survive the journey into orbit in one piece as well as function there. Apart from a few bought-in parts, the payloads were created in-house, i.e. computers were built and antennas produced, for which the University needed its own laboratory space. The chip design with 24 layers for the main computer, which is used in OPS-SAT and PRETTY, was also created in-house – merely the manufacturing was then handed over to an external contractor. For the assembly, there is a dedicated clean room at TU Graz’s Campus Inffeldgasse. But the production of the parts and the construction of the satellite are only one side. “Testing is actually the most critical part of space missions,” says Manuela Wenger.

A lot of infrastructure is needed for this. Since many parts are built in-house, they each have to undergo individual testing before the entire satellite itself also has to successfully complete a test course. It starts with testing temperatures from minus 40 to plus 80 degrees. For this purpose, the Institute of Communication Networks and Satellite Communications still has a climate exposure test cabinet from the times of AUSTROMIR in 1991 and is borrowing a second one from the Institute of Electronics. “We cool it down to minus 40°C and our cabinet is at plus 80°C and then you can really subject the satellite parts to extreme tests. Out of one, into the other, and then you can see whether the board or module can withstand it as it is meant to,” explains Manuela Wenger.

Destructive frequencies

There is also a vacuum chamber to see if the satellite has any air pockets and how the thermal transfer works. The integrated circuits in particular can heat up intensely and since only radiation and no conduction or cooling is possible in space, the thermal behaviour must be tested in a vacuum. Moreover, a satellite has to survive a rocket launch, which is why it is put on the distributing jigger during the test phase. What is crucial here is that the low frequencies of the rocket launch are not the same as the satellite’s own frequency, otherwise it would simply shatter. For the individual modules, there is a distributing jigger at TU Graz that can be loaded up to five kilograms. The whole satellite, including the ejection mechanism, requires the infrastructure of partners such as Beyond Gravity or SGS Germany.

In the seconds you wait there, you feel like you are aging a few years

The situation is different with tests in the antenna measurement chamber, which is available at the Institute of Microwave and Photonic Engineering at TU Graz. “There we test whether the satellite charges itself up electromagnetically, whether it interferes with itself when, for example, you switch on the flywheels, which can then cause the computer to run incorrectly or precipitate a sudden break in communication,” says Manuela Wenger. Newly developed antennas for the satellite can also be measured in the antenna measurement chamber.

When seconds feel like years

When all this is over and the satellite is stowed away in a rocket on the launch pad, the constructors are powerless. Will everything go well? Will the rocket get into orbit according to plan? Will the ejection work? Finally, there is particular tension before the first contact is made at the ground station. “In the seconds you wait there, you feel like you are aging a few years,” says Manuela Wenger. So far, contact has always worked and the commissioning phase, which requires particular attention in the first few weeks to fully activate the satellite, has also gone smoothly. But that does not mean that there’s no more excitement later.

This is especially true for TUGSAT-1, which was placed into orbit at an altitude of 780 kilometres, where many other satellites and space debris are travelling. This led to the North American Aerospace Defense Command (NORAD) calling twice to warn of collisions and advise TUGSAT-1 to take evasive action. But since the satellite has no propulsion of its own, this is not possible at all. “So, we were left biting our nails to see whether it would contact us again in the evening. Once it really happened that the closest approach was calculated at twelve metres, with the possible error margin being greater than twelve metres. The probability of collision was 16 percent,” recalls Manuela Wenger.

Keeping an eye on climate change

However, as all went well, work at the ground control could continue and, with the launch of PRETTY in 2023, hopefully it will continue to do so for some years to come. The new satellite will collect information on climate change and Manuela Wenger will ensure that the data collected reaches the researchers, while she and her colleagues make sure that PRETTY continues to work pretty well. And so, in this small room under the roof of the Inffeldgasse 12 building, work will continue to better understand planet Earth and its changing climate.

Would you like to receive the latest stories, news, research stories, interviews or blog posts from TU Graz directly on your smartphone or in your email inbox? Subscribe to the TU Graz Telegram newsletter free of charge.