Construction materials development and environmental interaction

Application of Waste-based Activators in One-part Alkali-activated Binder Systems

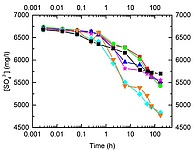

The reuse of mineral wastes is one of the most promising approaches towards a system that is handling its resources in a balanced form. Particularly in the construction and building sector, the concept of waste recycling could substantially ensure a low-carbon infrastructure. By developing waste-based, alkali-activated materials (AAM) as low energy alternatives, the construction industry could significantly benefit from these future building resources. Within the framework of the Christian Doppler Laboratory for waste-based geopolymer construction materials in the CO2-neutral circular economy (GECCO2), such AAM are developed to ensure a paradigm shift and move away from the current system. The key components of AAM are the precursor and alkali activator, of which both are preferentially sourced from available Austrian waste-streams. The majority of AAM, however, is activated with commercial sodium/potassium-based silicate solutions (waterglasses), which account for the highest energy demand and production cost during the manufacturing of AAM. This challenge is tackled in the course of GECCO2, where novel waste-based activators that will further incentivize energy efficiency during material production are developed. To successfully produce an alternative activator the following key parameters must be acknowledged:

- Selection mineral wastes appropriate for activator development (based on geochemical and mineralogical characteristics; e.g. high SiO2, high amorphous content)

- Pretreatment of wastes via thermochemical or hydrothermal procedures for derivation of sodium/potassium silicates

- Selection of appropriate waste-based binder systems, which are then activated with waste-based activators and tested for their respective mechanical properties and performance

Contact:

Sara Raič

Iris Zögl

Florian Steindl

Cyrill Vallazza-Grengg

High-resolution Luminescent Analysis of Construction Materials

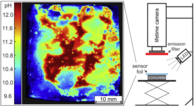

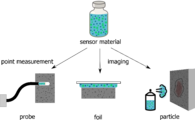

The pH value and the chloride concentration of concrete-based construction materials are key parameters for the assessment of their stability and long-term performances. Major types of chemical degradation mechanisms such as carbonation, chloride induced steel corrosion, as well as leaching and acid attack, usually directly correlate with their changes. Accordingly, a precise characterization of these critical parameters is a central factor for assessment of the state of repair of concrete constructions and the development of sustainable materials. The aim of this project is to explore luminescent analytical methods as an advanced (imaging) technique for the measurements of pH and chloride on concrete-based materials. This will enable better concrete diagnostics to improve the understanding of ongoing corrosion processes and allow a more accurate assessment of the state of repair of concrete constructions. The main objectives can be summarized as follows:

- Target-oriented development of a high-resolution imaging system for pH, chloride and potentially further relevant ions (e.g. potassium and calcium).

- On-site application of the measurement method as a simple, fast and economical analytical tool for the determination of the state-of-repair of concrete infrastructure (e.g. miniaturized probes and/or sensor particles).

- Improvement of the process understanding of important alteration processes in concrete and elaboration of recommendations for applications, building diagnostics, lifetime modelling and material development.

Contact:

Isabel Galan

Cyrill Vallazza-Grengg

Florian Mittermayr

Nanotechnology-based thermochromic materials for adaptive building envelopes

Thermochromic (TC) materials are smart materials characterized by a change in optical response with temperature. Their adaptive optical response to solar radiation has proven to be useful when implemented in building envelopes for improvement of energy efficiency and mitigation of environmental impact of urban areas, such as heat island effect.

Nanotechnology-based TC (nanoTC) materials offer the unique possibility of tailoring their optical properties. However, their implementation into building materials represents a clear research and technology challenge. Within the ‘Linka20220’ project nano-TC materials will be characterized at lab scale and proofs of concept will then be carried out.

Contact:

Isabel Galan

Florian Mittermayr

Durability aspects of shotcrete

Sprayed concrete, or “shotcrete”, is known to suffer from several chemical and mechanical degradation effects, including sulphate and chloride attack and calcium leaching. These attacks weaken the concrete and steel reinforcement or lead to unwanted calcium carbonate sinter formation. Using shotcrete with a higher durability against these hazards increases the service life of tunnels and underground buildings.

A technical objective of the ASSpC (Advanced Sustainable Sprayed Concrete) project is the development of durable and sustainable sprayed concrete to be used for construction and repair tasks. Increasing the sustainability of shotcrete ensures the economical use of resources in the context of a sustainable human development. To decrease the environmental impact of cement used in shotcrete production, substituting cement with supplementary cementitious materials and filler materials is getting more and more common. However, these additions alter the physical and chemical properties of the resulting shotcrete and therefore necessitate advanced research in the field of concrete durability.

Contact:

Andre Baldermann

Florian Steindl

Isabel Galan

Marlene Sakoparnig

Florian Mittermayr

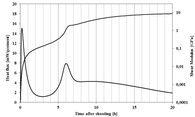

Sprayed concrete hydration

The rapid setting and strength evolution during the first hours after spraying are the two main requisites for shotcrete. These properties are directly related to the microstructure development: formation of hydrated phases and pore structure. Detailed understanding of the early hydration reactions in shotcrete is crucial for the optimization of mixing and processing. However, the need of spraying equipment, together with the high speed of the reactions make laboratory analysis of these materials challenging.

Within the frame of the ‘Advanced and sustainable sprayed concrete’ (ASSpC) project, new mixing approaches are being developed with the final aim of reducing the impact of shotcrete on the environment. Mechanical performance and durability properties are being optimized for these new approaches. In parallel, the hydration reactions occurring in these systems are being studied (e.g. by isothermal calorimetry, shear modulus measurement, XRD and SEM) to gain deeper knowledge on their hydration and setting behavior and to optimize processing.

Contact:

Isabel Galan

Florian Steindl

Advances in concrete materials for sewer systems affected by microbial induced concrete corrosion

The efficient, safe and cost-effective collection and transport of sewage is a key criterion maintaining expected sanitary standards of modern society. Microbial induced concrete corrosion (MICC) is accounted for ~40 % of the degradation of concrete based subsurface wastewater infrastructure globally. The current state of the art does not provide a sustainable construction material, which meets the long-term requirements in such aggressive and corrosive sewer environments.

Within this project, we aim to close the existing gap between materials science (different binder types) and microbiological interactions for application of new innovative construction materials, with increased performance and functionality. Key objectives are: O1) to characterize role of physiochemical characteristics of conventional cement-based materials on biofilm adhesion, composition and growth and subsequent comparison to objective O2. O2) to characterize microbiological growth on innovative concrete materials; influence of physical material properties on microbial growth, biofilm characterization and structure, microbial community composition, evaluation of antimicrobial additives. O3) to establish multi-functionalities for the novel tailored concretes (acid resistance, antimicrobial effects, and versatility: encouraging wide application range in concrete structures as well as sprayable repair mortars).

Contact:

Cyrill Vallazza-Grengg

Florian Mittermayr