Eveline Kuhnert, Madeline Dächert, Michael Lammer, Lukas Roessler-Escudero, Özge Kiziltan, Eduardo Machado-Charry, Viktor Hacker, Merit Bodner

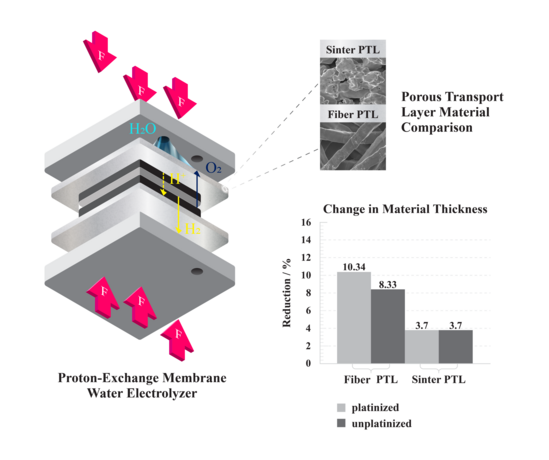

The porous transport layer (PTL) in proton exchange membrane water electrolysis (PEMWE) accounts for

approximately 17–25% of total stack cost and its durability and structural stability are crucial for system per-

formance and lifetime. Due to the harsh conditions on the anode, corrosion-resistant titanium fiber or sintered

PTLs are required. However, the mechanical behavior of these materials under compression and in particular

under varying conditions, remains insufficiently understood.

In this study, a mechanistic understanding of compression-induced performance hysteresis in titanium PTLs

through in-situ stress tests and ex-situ mechanical and structural characterization is acquired. Fiber-based and

sintered Ti-PTLs, with and without Pt coating, were subjected to cyclic compression during PEMWE operation to

evaluate the evolution of contact behavior, performance, and morphology. Results show a compression-induced

performance hysteresis and irreversible deformation and degradation. Fiber PTLs show greater initial perfor-

mance but are more prone to permanent compaction, while sintered PTLs maintain structural rigidity but exhibit

less adaptive contact formation. Platinized PTLs generally demonstrate higher resistance to mechanical fatigue.

This work provides practical guidance for PEMWE stack assembly and PTL selection and thereby enables the

definition of compression boundaries and PTL architecture recommendations. This allows to minimize me-

chanical fatigue and extend PEMWE operational durability, therefore supporting more cost-effective and robust

clean hydrogen production.

Results in Engineering

DOI: 10.1016/j.rineng.2025.108109

Link to Article