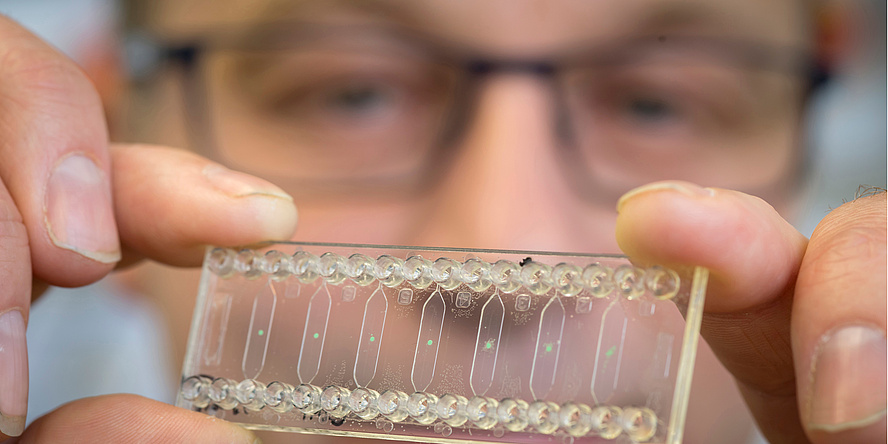

Microbioreactors are miniaturised bioreactors with structures on the micrometre scale. They are a special field of microfluidics or lab-on-chip technology and consist of chambers and channels in sizes from 10 μm to 3 mm and depths from 10 to 800 μm. They are made of glass, silicone or polymeric materials. Compared with conventional bioreactors, and thanks to their small volume and shorter transport distances, microbioreactors are characterised by faster heat transport, improved reaction control, reduced safety risk, fewer material and energy requirements, and greater product yield. They allow the production of small amounts in batch, but also continuous production. Microbioreactors allow us to perform experiments in controllable test conditions and have the potential for use in all chemical and biochemical applications, e.g. industrial processing, process optimisation, preparation of personalized medicine and in laboratories for research and development.

Small scale

Microbioreactors are made in customized designs, ranging from simple chambers to meanderlike structures or chambers packed with particles, socalled packed bed reactors. Special structures can be implemented to achieve a good mixing of the reactants.

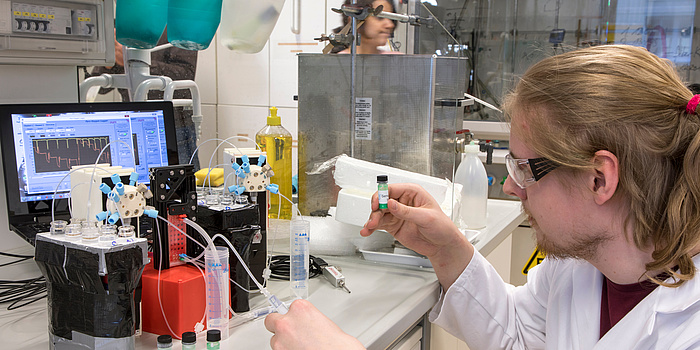

Typical set-up of microfluidic reactors. Reagents and fluids are injected into the reactor using syringe pumps. The reaction can be controlled in real-time with the integrated sensors.

Microbioreactors are applied in various application fields, e.g. enzymes are immobilised on the surface of the channel walls to perform fast biocatalytic transformations at the micro scale. This enables the re¬use or recovery of expensive enzymes or continuous processing in the flow. Microbioreactors are also employed for the investigation and optimisation of diverse process parameters. Researchers in process engineering aim to determine the best process conditions to optimise large¬scale processes. The newly developed tools will provide a better understanding of processes and simplify and accelerate their optimisation. Microbioreactors are also used for cell culturing. Microfluidic systems and cell cultures are a perfect match because of their comparable sizes. In comparison to static culture dishes or shake flasks, they enable microfluidics nutrient supply under relevant shear force condition to be carried out as they can be found under physiological conditions. In addition, cell culture conditions can be adjusted by automated fluid handling with a high reproducibility.

Accelerated research

Microbioreactors offer the possibility to accelerate research and development in these fields due to the small sizes and a precise control of the micro environment. Integrated analytics are essential to achieve a continuous monitoring and deeper insight into the processes or biological systems investigated. The key parameters measured in microbioreactors are oxygen and pH. Optical chemical sensors are beneficial compared to other analysis techniques. They are easy to integrate, are noninvasive, and can be measured contactlessly from outside the reaction chamber. However, the smallscale demands highperformance sensor materials and measurement systems. Optical chemical sensors are composed of luminescent dyes embedded in a polymer film. The interaction of the analyte (oxygen or hydrogen ions) alter the luminescent properties of the dye which carries the analytical information. The sensors are integrated into the microsystem as thin films or spots in sizes of 100 to 750 μm using inkjet printing and can be read out contactlessly from outside by optical fibres. Alternatively, analyte sensitive nanoparticles are applied, and these can be directly injected into the fluid without an integration step.

The team of the Institute of Analytical Chemistry and Food Chemistry and the Institute of Biotechnology and Biochemical Engineering working with microbioreactors.

The integrated sensors enable biocatalytic conversions to be measured and the nutrient supply in cell cultures to be monitored. The measurement of metabolism rates with oxygen, pH and glucose sensors tailormade for cell cultures has a high potential. The combination of these sensors allows exploration of the bioenergetics of mammalian cells to be performed. This measurement can deliver valuable information on the toxicity of drug candidates and nanomaterials. These sensors are also important tools in the emerging organ-on-chip technology, which mimics the functionality of human organs using 3D-tissues co-cultures in microfluidic devices.