Project Description

Approximately 20% of the European Union’s carbon dioxide emissions originate from road traffic. About two thirds of these emissions originate from passenger cars. Due to the low overall efficiency of conventional cars (about 18% in the New European Driving Cycle) a significant reduction of the emissions can be achieved. Two different approaches are being considered: Hybridization of the vehicle has the potential to reveal an overall efficiency close to the optimal efficiency of the internal combustion engine leading to a reduction of emissions by up to 55%. On the other hand, electric vehicles can be used allowing emission free driving. However, currently available hybrid and electric vehicles are not competitive compared to conventional cars, primarily due to the deficiencies of the electrochemical storage devices used (battery, supercap). For example, 75 kg of lithium ion cells are required to provide the energy content stored in a single liter of diesel fuel. Moreover, even though intensive research has been performed it is not possible to build a battery system that fulfils the demands concerning power and energy density, efficiency, life span, and costs.

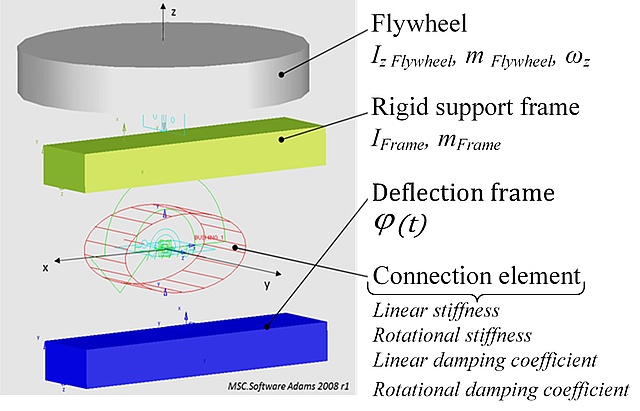

A competitive electric vehicle can only be built when using two separate energy storage components, namely a high-energy and a high-power storage device. The optimal energy storage device is a battery optimized for maximum energy content while an electro-mechanical flywheel storage seems to be the most suitable choice for the high-power energy storage. In case of a hybrid vehicle only the high power device is needed since the internal combustion engine or fuel cell system provides the main part of the driving power.

Flywheel systems are also favorable considering economic and ecological aspects since their production does not require any limited resources and the system can be recycled easily. Within the project, different concepts to implement flywheel storages will be developed with respect to their applicability in passenger cars. This comprises the investigation of technical requirements (power limit, energy density, lifetime) as well as efficiency of the energy storage and target cost. The project involves the following research topics:

- Acquisition (simulation and measurement) of typical load profiles of the flywheel used as high-power energy storage inside vehicles of different technologies (hybrid vehicles, electric vehicles, vehicle concepts using batteries/fuel cells).

- Design and optimization of the bearing as well as the electrical machine in order to fulfil the identified requirements.

- Crashworthiness of flywheel storages and behavior in case of system malfunction.

Project Data

Project Type: Joint Proposal

Program: FFG New Energies 2020 – 3rd Call

Duration: 3 years

Status: Finished

Workgroup: Energy Aware Systems