The latest developments in welding

A driver of innovation in medicine

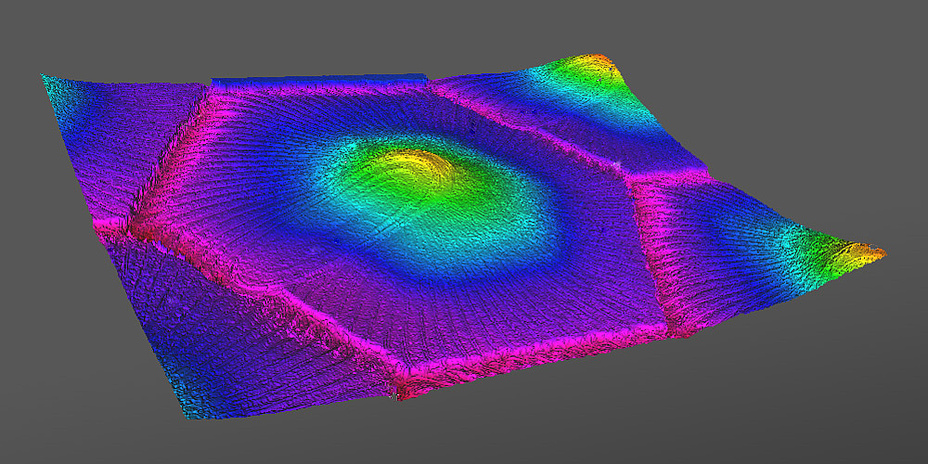

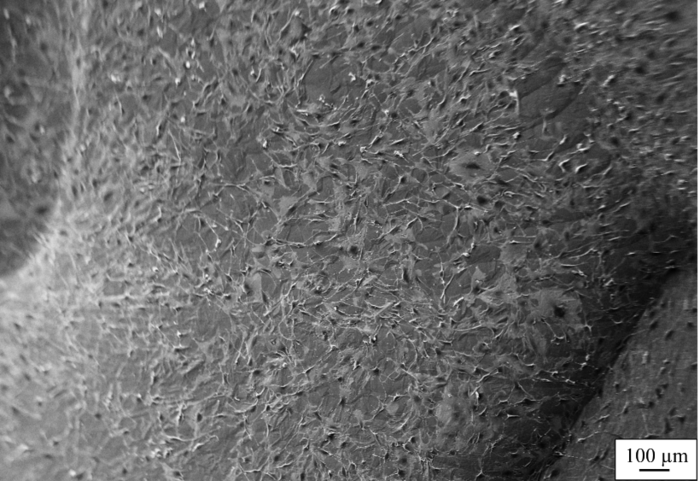

Electron beam surface treatment is particularly interesting for innovations in the field of medical engineering. In cooperation with the Department of Orthopaedics and Orthopaedic Surgery at the Medical University of Graz, the Institute of Materials Science and Welding at TU Graz is working on a new generation of implants. Currently the insertion of implants may lead to complications such as postoperative infections. This is due to the low degree of adherence of the tissue to the implant material and implant slipping. As a result the tissue is irritated and a cavity is formed in which bacteria can spread. "However, we can now improve the adherence of the tissue by manipulating the surface structure of the implant," says Claudia Ramskogler from the Institute of Materials Science and Welding, who is researching this topic. "With electron beam technology we are able to uniquely treat the surface structure of the metallic material, in this case titanium alloys."

Power plant construction and similar applications

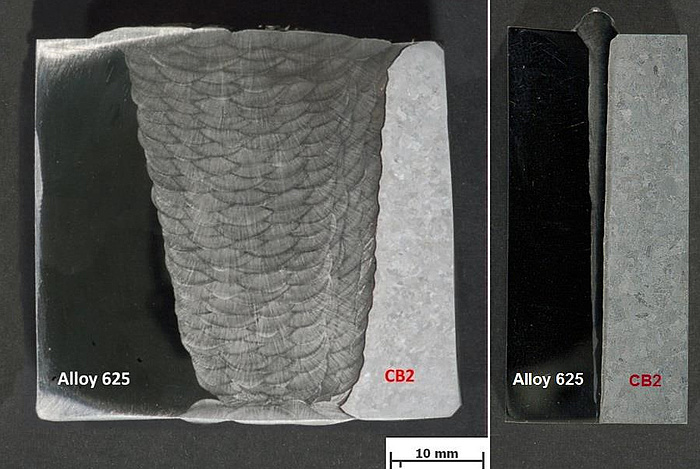

The thick-walled parts of the power stations are exposed to enormous steam pressures and temperatures – a formidable challenge for materials research, and on that will further increase as the world’s energy demand keeps growing. If the efficiency of the power stations is to be improved any further, the steam pressure and the temperature in the power stations needs to be increased. This will require materials able to withstand these conditions. One possibility would be to continue relying on relatively inexpensive high temperature-proof chromium steel for the manufacture of most power station components, while temperature and pressure-critical parts could be made of the so-called nickel basis superalloys. Until recently, the question was whether it is possible to achieve a "power station-proof" welding joint between these superalloys and chromium steel. This is precisely where the electron beam welding system comes in. On a commission of the Traisen foundry – a Voest-Alpine company – the Institute of Materials Science and Welding at TU Graz showed that electron beam welding is a very suitable technique to join these two materials. The 50 mm thick welding seam successfully passed the subsequent standardised tests, and the welding process took less than one minute.The electron beam welding facility can also be used for the production of alloys. The Institute of Electron Microscopy and Nanoanalysis at TU Graz produced a nickel copper alloy that was then used for further material analyses. "We are still experimenting with several materials in this field, the system might conceivably even be suitable for the production of alloys from any number of elements," explains Coline Béal, university assistant at the Institute of Materials Science and Welding at TU Graz.

Electron beam technology is also finding its way into automotive industry, for example for gearboxes, and high-end applications in the fields of aviation and aerospace. "Distortion-free welding of small parts is also possible here – this would not be possible with conventional welding methods," states Norbert Enzinger. At the same time, feasibility analyses for many other applications are also being conducted.

Kontakt

Assoc.Prof. Dipl.-Ing. Dr.techn.

Institute of Materials Science and Welding

Kopernikusgasse 24

8010 Graz, Austria

Phone: +43 316 873 7182

<link int-link-mail window for sending>norbert.enzinger@tugraz.at

<link http: iws.tugraz.at _blank int-link-external external link in new>iws.tugraz.at

![[Translate to Englisch:]](https://www.tugraz.at/fileadmin/_processed_/9/8/csm_banner-thek-by-privat_a42f57f7b3.jpg)